From Single Prototypes to Millions of Parts—We Scale With You

Whether you're building a concept model or scaling to mass production, Quick2MFG delivers high-precision manufacturing tailored to your needs. We specialize in transforming your 3D designs into physical products—ranging from single prototypes to hundreds of production-grade parts, thousands of functional units, and even millions of consumable components.

Over the past 20+ years, we've supported startups, engineers, and enterprise customers with flexible solutions—leveraging technologies like 3D printing, CNC machining, vacuum casting, injection molding, and automated production systems.

Our Core Services

CNC Machining

Precision Machined Parts — Metal & Plastic

We provide 3-axis, 4-axis, and 5-axis CNC machining for tight-tolerance components made from a wide range of engineering-grade materials. Ideal for both functional prototypes and low-volume production.

Tolerances as tight as ±0.005mm

Aluminum, stainless steel, titanium, PEEK, and more

Surface finishing available: anodizing, powder coating, bead blasting

Injection Molding

Rapid Tooling & Scalable Production

Need thousands of units? Our injection molding services are built for speed and scalability—perfect for bridge production and high-volume product runs.

Quick-turn aluminum tooling

Over molding and insert molding

Millions of units delivered—including disposable medical components

Rapid Prototyping

Accelerate Your Product Development

Bring your concepts to life fast. We offer multiple prototyping technologies to help you test fit, function, and appearance—before committing to production.

Technologies: 3D printing, CNC machining, RTV casting

Same-day or 2–3 day turnaround available

Ideal for investor demos and early market testing

RTV Casting

Small-Batch Production Without Tooling

Need dozens of parts but not ready for molds? RTV casting is perfect for 10–100+ units, offering fine details, smooth finishes, and fast lead times.

RTV (Room Temperature Vulcanization) casting, also known as urethane casting, vacuum casting or silicone molding

Polyurethane resins mimicking ABS, rubber, or silicone

Clear, flexible, or custom-colored parts

No steel tooling required

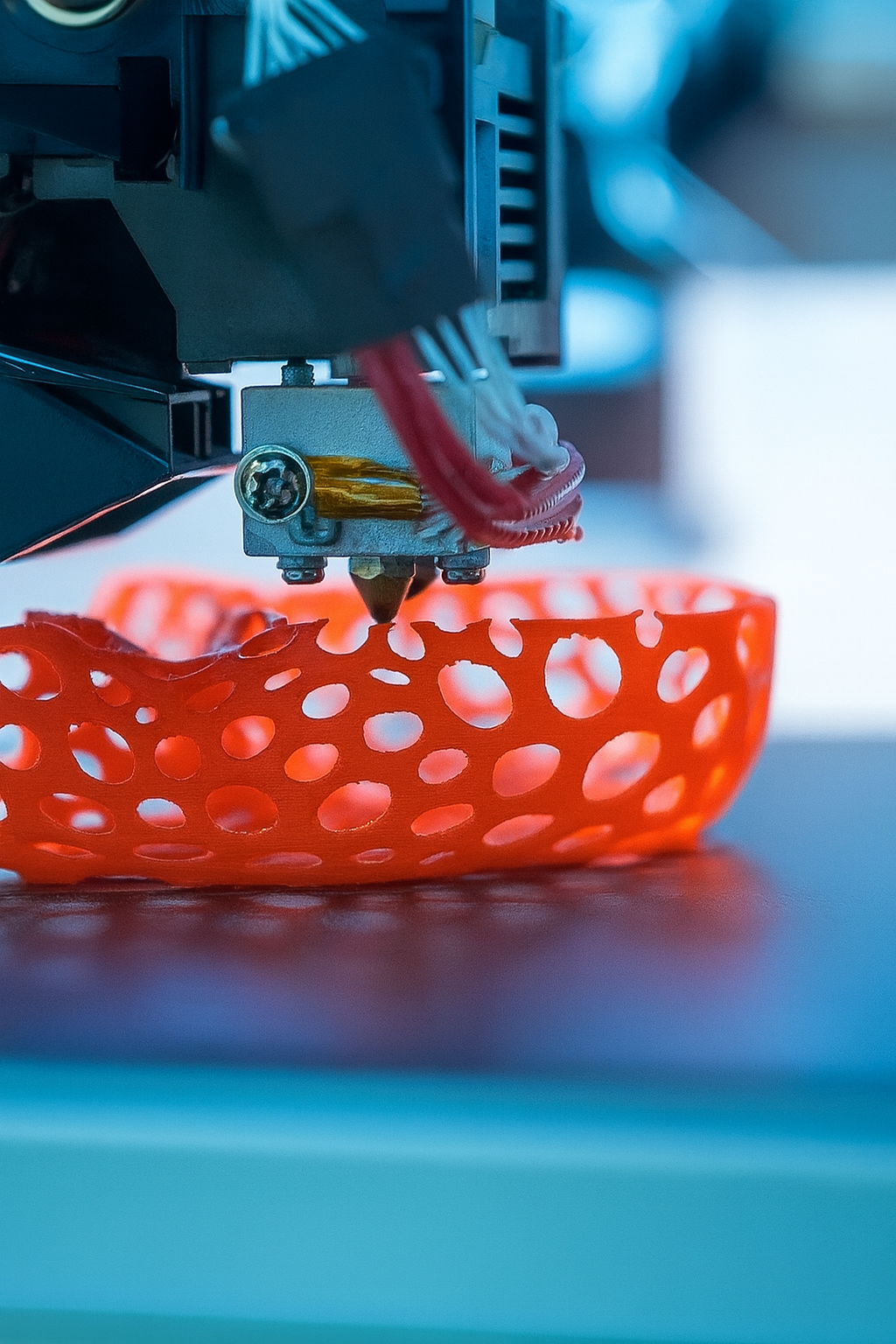

3D Printing

Functional Prints with Speed & Accuracy

Our additive manufacturing options let you iterate quickly and cost-effectively. Perfect for early validation or low-use functional components.

SLA, SLS, FDM, and MJF options

Rigid, flexible, and transparent materials

Upload CAD files directly for quote

Finishing Services

Final Touches that Perform & Impress

Enhance durability, appearance, and user experience with professional-grade finishing.

Finishes: anodizing, chrome plating, painting, laser engraving, silk-screening

Surface smoothing and texture options

Cosmetic vs. functional finishing guidance available

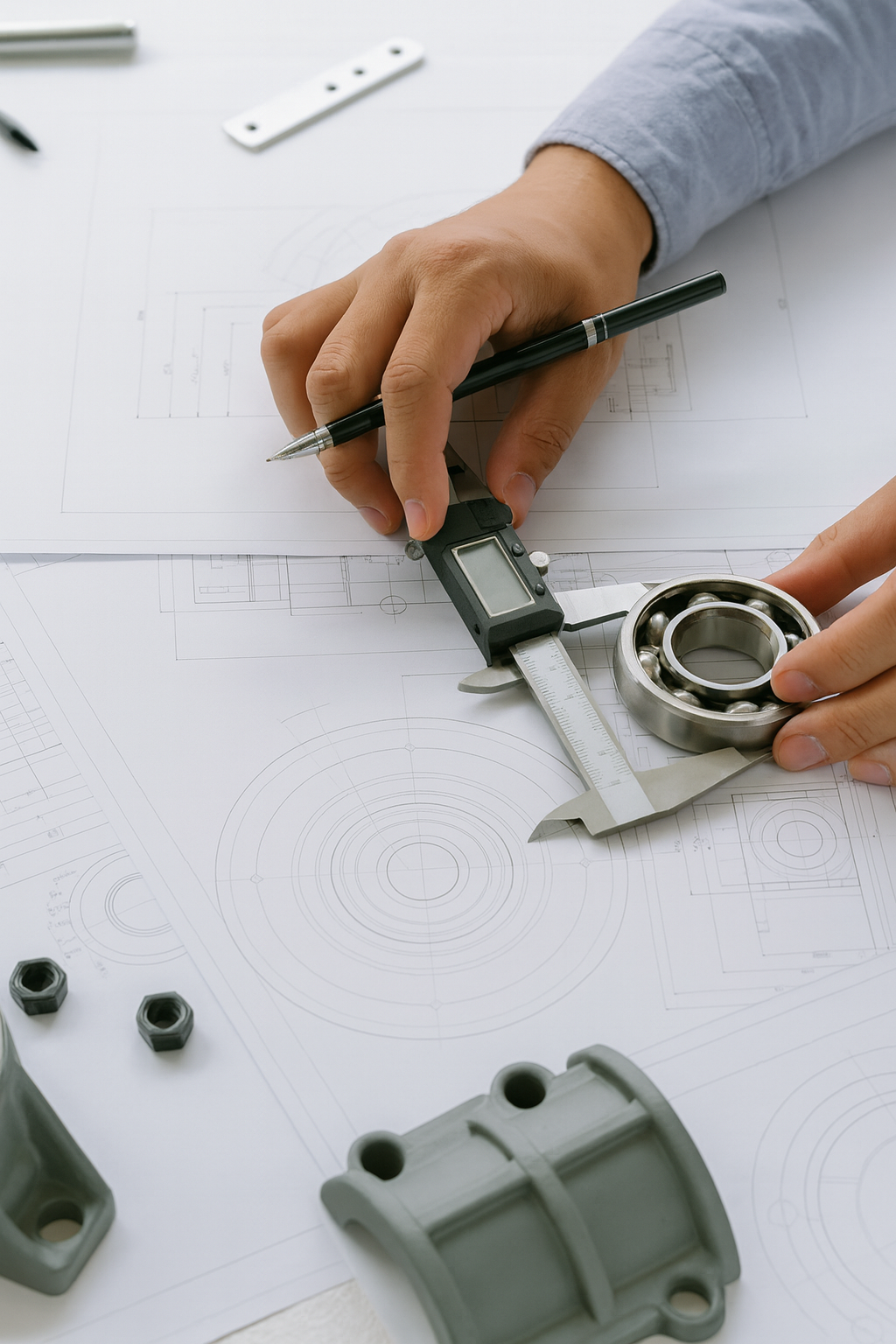

Design for Manufacturing (DFM) Review

Optimize Before You Build

Every project includes a free DFM review—our engineers help ensure your design is optimized for speed, cost, and repeatability.

Catch potential design issues early

Improve yield and assembly ease

Fast feedback within 24–48 hours

Built for All Stages of Production

From single 3D-printed prototypes to hundreds of vacuum-cast or CNC-machined units, and up to mass-manufactured products through injection molding and automation—Quick2MFG is your U.S. partner for scalable, end-to-end manufacturing.

Ready to Build Something?

Our U.S.-based team is ready to help you choose the right service, process, and material to fit your goals.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!